P1 : 60 ÷ 100 mbar - P2 : 13,7 ÷ 30 mbar

|

CODE |

ATTACCHI |

Q min |

Q max |

|

ST846-15-A |

DN15 (G 1/2” FF) |

1 m3/h |

10 m3/h |

|

ST846-20-A |

DN20 (G 3/4” FF) |

0,8 m3/h |

8 m3/h |

|

ST846-25-A |

DN25 (G 1” FF) |

0,9 m3/h |

9 m3/h |

COMPONENTS

1. Plastic cup

2. Regulation spring

3. Cover

4. Diaphragm

5. O-ring

6. Obturator

7. Bottom cover

8. Obturator pin

9. Filtering organ

10. Operating diaphragm

11. Diaphragm plate

12. Diaphragm fi xing nut

13. Setting screw

TECHNICAL FEATURES

Model: A and A/SF

Spring Code: 847/1

P1: 60 ÷ 100 mbar

P2: 13,7 ÷ 30 mbar

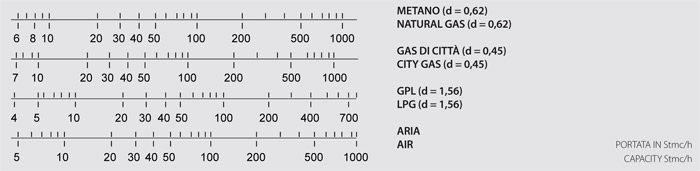

Q min : see performances graph

Q max : see performances graph

Ref. Standard: EN 88-1

Type of gas: I°, II° and III° family

Class: A

Group: 2

Ambient Temp.: -15°C ÷ +60°C

Connections: UNI ISO 7/1

Certifi cate CE No. 51BS3443

DESCRIPTION

Gas pressure governor series ST 846-A DN 15 - DN 20 - DN 25

This device, due to its accuracy regulation, it is particulary suitable for small systems

and where the gas is distributed in a not uniform manner.

ATTENTION!!! THE FOLLOWING OPERATIONS SHOULD BE DONE BY TECHNICAL SPECIALIST.

INSTALLATION

The Governor is normally placed before the gas meter. It should be installed having the arrow (printed on the governor body) pointing toward gas meter and in vertical position. Close to the outlet connection there is a pressure point (as per UNI 8978) where it is possible to verify the regulated outlet pressure.

CALIBRATION

Before starting the installation, make sure the supplied spring is adjusted to the desired set pressure. After removing the plastic cap (1), place the pressure regulator (13) to the minimum setting (fully unscrewed). Then start the system, controlling the pressure adjustment screw on the regulator itself until the desired pressure.

OUT OF ORDER

Unscrew the cap (1) and turn the setting screw (13) until its limit.

CAPACITY’S COMPARATIVE SCALE